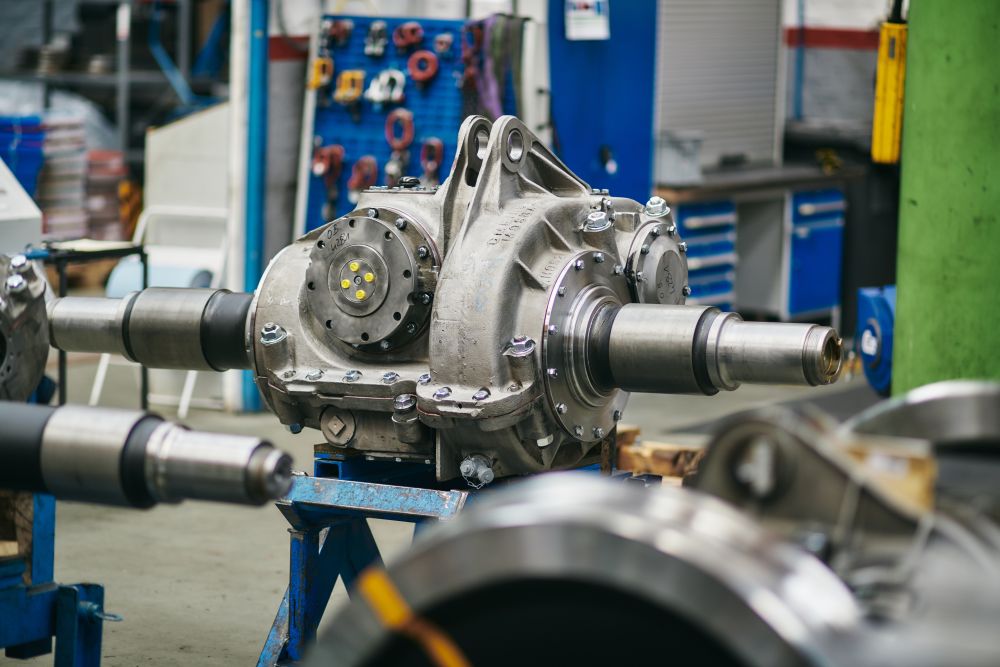

Deutsche Bahn (DB) has reached a milestone by producing 100,000 spare parts using 3D printing technology. This breakthrough demonstrates the transformative power of 3D printing to revolutionize maintenance operations in the railway industry. Among the 100,000 parts, the largest and heaviest is a gearbox housing for shunting locomotives, which weighs 570 kilograms and takes up almost one cubic meter in volume.

The utilization of 3D-printed spare parts brings immense advantages. In particular, the rapid production process means that around 370 locomotives can be repaired and returned to service more efficiently. In the past, these parts would have been sourced from the locomotive manufacturer with an average lead time of ten months. However, by using 3D printing technology, DB has reduced the lead time to just two months. The gearbox housing is produced using an indirect 3D printing method known as binder jetting. This technique involves combining a powdered material with a liquid binder to create a mold, which is later used to cast the gearbox housing.

"3D printing is transforming maintenance. It saves time, costs, and resources because we can produce spare parts almost on-demand through a 'digital warehouse' and do not require a large inventory. In times of global supply shortages and resource scarcity, 3D printing is more important than ever,” said Daniela Gerd tom Markotten, DB Board Member for Digitalization and Technology.

DB is gradually expanding a database that stores virtual technical drawings of spare parts. Currently, DB's digital warehouse houses approximately 1,000 virtual models, with plans to expand the collection to around 10,000 different components by 2030. This digital repository enables the rapid and convenient production of 3D-printed components with just a few mouse clicks. As a result, DB saves on logistics space, reduces storage costs, shortens supply chain links, and gains greater independence.